410 Stainless Steel Plate

410 Stainless Steel Plate Specification

- Product Name

- Stainless Steel Products

- Steel Type

- Stainless Steel

- Steel Product Type

- Steel Plates

- Grade

- 202, 304, 316

- Thickness

- 3MM- 100MM Millimeter (mm)

- Shape

- Plate

- Steel Standard

- ASTM

- Surface

- Mill Finished

- Application

- Door & Window

- Dimension (L*W*H)

- 4x8 and as per customized Foot (ft)

- Weight

- As per sheet Kilograms (kg)

- Color

- Grey

410 Stainless Steel Plate Trade Information

- Minimum Order Quantity

- 100 Kilograms

- FOB Port

- Yes Available

- Supply Ability

- 100000 Kilograms Per Week

- Delivery Time

- 7 Days

- Packaging Details

- As per customer request

- Main Domestic Market

- All India

- Certifications

- Test Certificate

About 410 Stainless Steel Plate

A 410 stainless steel plate is a type of stainless steel plate that belongs to the martensitic family of stainless steels. It is known for its excellent mechanical properties, high strength, and moderate corrosion resistance.

The main alloying element in 410 stainless steel is chromium, which provides it with corrosion resistance and the ability to withstand high temperatures. The chromium content in 410 stainless steel is typically around 11.5% to 13.5%. Additionally, it contains a small amount of carbon (around 0.08% to 0.15%) to promote hardness and strength.

410 stainless steel plates are commonly used in applications that require resistance to corrosion and moderate mechanical properties, such as manufacturing of pump and valve parts, cutlery, kitchen utensils, surgical instruments, firearms, and automotive parts. It is also suitable for applications where heat treatment is necessary to achieve desired hardness and strength.

These plates are available in various sizes and thicknesses to meet specific project requirements. They can be further processed and fabricated through cutting, bending, and machining operations.

While 410 stainless steel exhibits good corrosion resistance in mild environments, it may not be as resistant as other stainless steel grades in more aggressive corrosive environments. However, it can be hardened and strengthened through heat treatment processes such as quenching and tempering.

Overall, 410 stainless steel plates offer a combination of mechanical strength, moderate corrosion resistance, and heat treatability, making them suitable for a wide range of applications where durability and resistance to wear and corrosion are required.

Price 160 INR/ Kilograms

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 100000 Kilograms Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Sheet And Plate Category

321 Stainless Steel Plate

Price 240 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Steel Product Type : Steel Plates

Steel Type : Stainless Steel

Product Name : Stainless Steel Products

Application : Construction

901l Stainless Steel Plate

Price 240 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Steel Product Type : Steel Plates

Steel Type : Stainless Steel

Product Name : Stainless Steel Products

Application : Construction

347 Stainless Steel Plate

Price 240 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Steel Product Type : Steel Plates

Steel Type : Stainless Steel

Product Name : Stainless Steel Products

Application : Construction

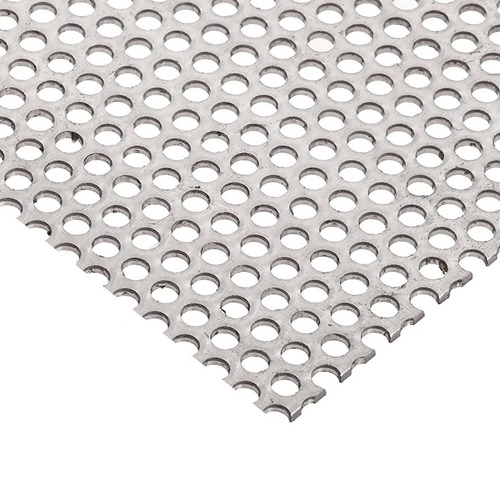

304 SS Perforated Sheet

Price 35 INR / Square Foot

Minimum Order Quantity : 50 Square Foots

Steel Product Type : Steel Sheets

Steel Type : Stainless Steel

Product Name : Steel Products

Application : Hardware Parts